What Does Spandrel Panel Window Do?

Along with including rehabilitation technique, methods to decrease condensation possibility during layout include: Normally drape wall surface systems have greater resistance to condensation than store front systems. Utilizing drape wall is one method to decrease, or delay the onset of condensation development. spandrel glass panel. At Pie, we provide 2-D thermal modeling (THERM) to help our clients with the layout of spandrel locations.

By knowing surface temperatures, Pie is able to figure out under which conditions condensation will occur, along with recognize shift factors at which condensation will not create, making it much easier to anticipate as well as remediate. On top of that, numerous arrangements can be modeled to optimize indoor surface temperatures. Setting up back pans right into the spandrel infill glazing pocket, which are vented to the exterior with insulation outboard of the frying pan, advertises raised indoor surface temperatures with the included benefit of minimizing warmth transfer with the spandrel infill.

It is feasible to make the most of interior surface area temperature levels by eliminating the usage of insulation at the spandrel infill place. Bear in mind if you develop without insulation at spandrel infill locations, there will certainly be a greater energy loss via the setting up as well as for that reason bigger HVAC warmth loads. At Pie, we can aid you each action of the way, whether you just recently uncovered condensation as well as are trying to find removal as well as monitoring solutions, or whether you are developing a building and purpose to decrease the capacity for condensation at spandrel infill locations.

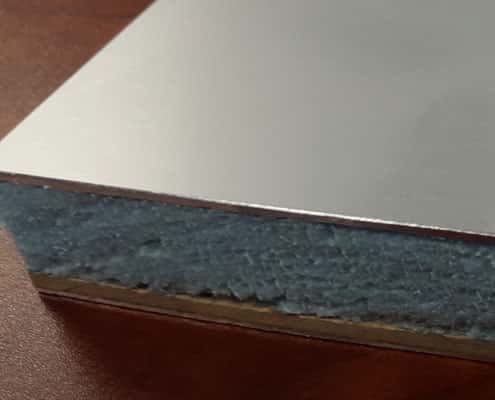

Enhance R-Values Without Compromising Layout! Glazing infill panels are created to be 'glazed' right into a light weight aluminum home window system instead of glass (spandrel glass panel). They provide many advantages to designers and structure owners trying to find inexpensive as well as aesthetically pleasing alternatives for their structures. Insulated panels contain 3 various layers- an inflexible insulation core sandwiched in between a completed concrete face as well as back.

Utilized as a home window substitute, Synstone infill panels boost the thermal performance of window openings. This reduces the expense of possession by allowing savings on cooling and heating. Synstone infill panels consist of non-asbestos glass fibre reinforced concrete confront with foam core insulation. Synstone infill panels can be manufactured to R= 24 insulation value.

The Spandrel Insulation Statements

The term spandrel panel may additionally be utilized to refer to cladding panels that fill the room over the head of a home window on one flooring and also below the cill of the window on the following flooring on skyscraper structures. These panels conceal the flooring structure. If they are made from opaque or translucent glass, this might be described as spandrel glass.

Where there is no information regarding the panel or there is unpredictability, it will certainly be necessary to check out the panel structure by sample screening." Ref https://www.gov.uk/government/publications/advice-for-building-owners-on-spandrel-panelswindow-panelsinfill-panels-on-external-walls NB The term spandrel light beam describes an outside beam of light that expands from one column to an additional, bring an outside wall surface load.

Glaz-Tech Industries presents GlazeGuard 250WR as well as GlazeGuard1000 WR infill panels to more provide added building options for storefront as well as home window systems. Its durable as well as eye-catching design contributes with store front applications as well as shielded units. Glaz-Tech's infill panels offer numerous building benefits: GlazeGuard WR panels are very reliable versus moisture intrusion as well as also ideal for setup as a result of its light-weight design.

The smart Trick of Spandrel Panel Definition That Nobody is Talking About

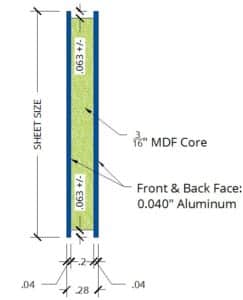

Please contact your neighborhood sales agent for other color queries as well as product schedule. Product Review: GlazeGuard 250 WR is a composite panel for usage as a glazing infill made by laminating 2 prefinished aluminum skins to a substratum of high thickness polypropylene. These panels are designed for usage as a substitute or enhance to glass in windows, storefront, discreetness screens, railing inserts, and so on.

Element Standard (in) Metric (mm) Prefinished Distinctive Light Weight Aluminum Skins.010".254 mm Prefinished Smooth Aluminum Skins.024".609 mm High Thickness Polypropylene Core 1/4" 6.00 mm view it now Residential property Requirement (in) Metric (mm) Panel Weight (spandrel panel detail).72 lbs/ ft 3.51 Our site kg/ m Small Thickness 1/4" 6mm GlazeGuard 1000 WR is a composite panel for usage as a polishing infill made by laminating 2 prefinished light weight aluminum skins to substrates of high density polypropylene.

These panels are created for usage as a replacement or complement to glass in windows, store front, discreetness displays, barrier inserts, etc. Similar in thickness to GlazeGuard 1000 (both are 1"), these panels offer more water resistance than the toughened up hardboard structure. Part Requirement (in) Metric (mm) Prefinished Textured Aluminum Skins.010".254 mm Prefinished Smooth Aluminum Skins.024".609 mm High Thickness Polypropylene Stabilizers 5/32" 4.00 mm Enhanced Polystyrene Foam (EPS) Core 5/8" 15.9 mm Polyisocyanurate Foam (ISO) Core 5/8" 15 - spandrel panel.9 mm Building Requirement (in) Metric (in) Panel Weight 1.05 lbs/ feet 5.12 kg/ m Nominal Thickness 1" 25 mm.